Jan 13 2023

Aug 05 2022

Aug 05 2022

Jul 29 2022

12B/13B, North Building of Pacific Square, No.331, Jiahe Road, Siming District, Xiamen, Fujian, China. 361001

+86-592-5065811

+8615160739809

Why Choose MQ STONE's Engineered Quartz Countertops For Residence Projects

Kitchen countertops must be long-lasting, stylish, and simple to clean and maintain. While several countertop materials have some advantages, quartz countertops have all of them.

Quartz countertops have earned a reputation as a high-end surface material during the previous few decades. However, acquiring respect has been a slow process. Even today, quartz counters compete for space in kitchens and bathrooms with Engineered Quartz solid surface materials.

What is quartz stone?

MQ STONE's quartz stone is a new type of stone made of 92% quartz sand powder and 8% resin, pigment, and other auxiliary materials pressed and shaped under high pressure and high temperature in a vacuum state, which is an environmentally friendly and green new building and decorative material without radioactive pollution and can be reused. The main fillers of quartz are silica, quartz sand, quartz powder, crushed glass, shells, sea sand, etc., which have the characteristics of high density and high purity. In the production process of quartzite, Dupont titanium dioxide imported from the United States is specially added, which can maintain the wetness of the plate, and the color will not fade in long-term use. By adding pigments, different colors of quartz stones can be produced, making it colorful.

So how is quartz stone processed? And Why Choose MQ STONE Quartz Series?

1:Unique back to the furnace process the quartz sand, titanium dioxide, and other raw materials used in quartz stone are unified in the mixer mixing, to ensure that the raw materials of the same batch in the production of raw materials without color differences before. 2:Resin color paste disperser can disperse 156 sheets/batch of resin used in quartz stone. According to the temperature change, the engineer divides the production into three periods of dispersing resin in the morning, middle and evening to avoid the subtle color difference of the sheet caused by the temperature change.

2:Resin color paste disperser can disperse 156 sheets/batch of resin used in quartz stone. According to the temperature change, the engineer divides the production into three periods of dispersing resin in the morning, middle and evening to avoid the subtle color difference of the sheet caused by the temperature change.

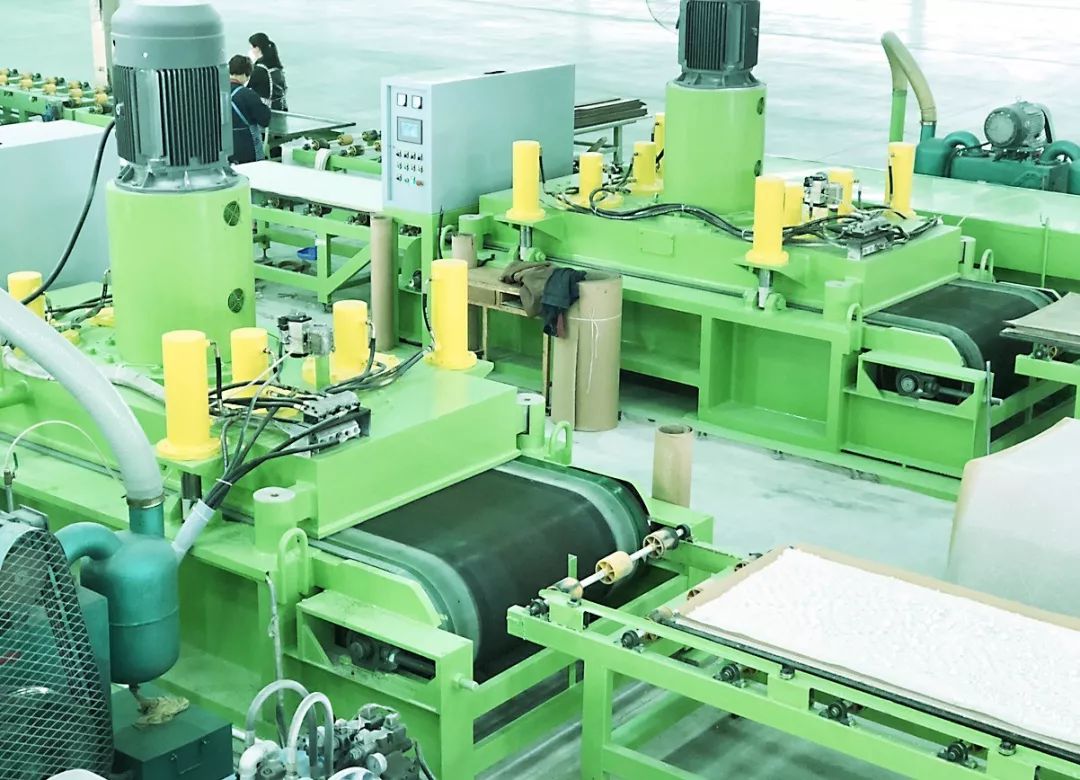

3:Automatic mixing machine adopts a fully automatic pipeline conveying system and closed mixing process combined with the principle of planetary rotation and rotation to ensure more detailed and uniform mixing of raw materials and fully guarantee the integrity of quartz stone sheets.

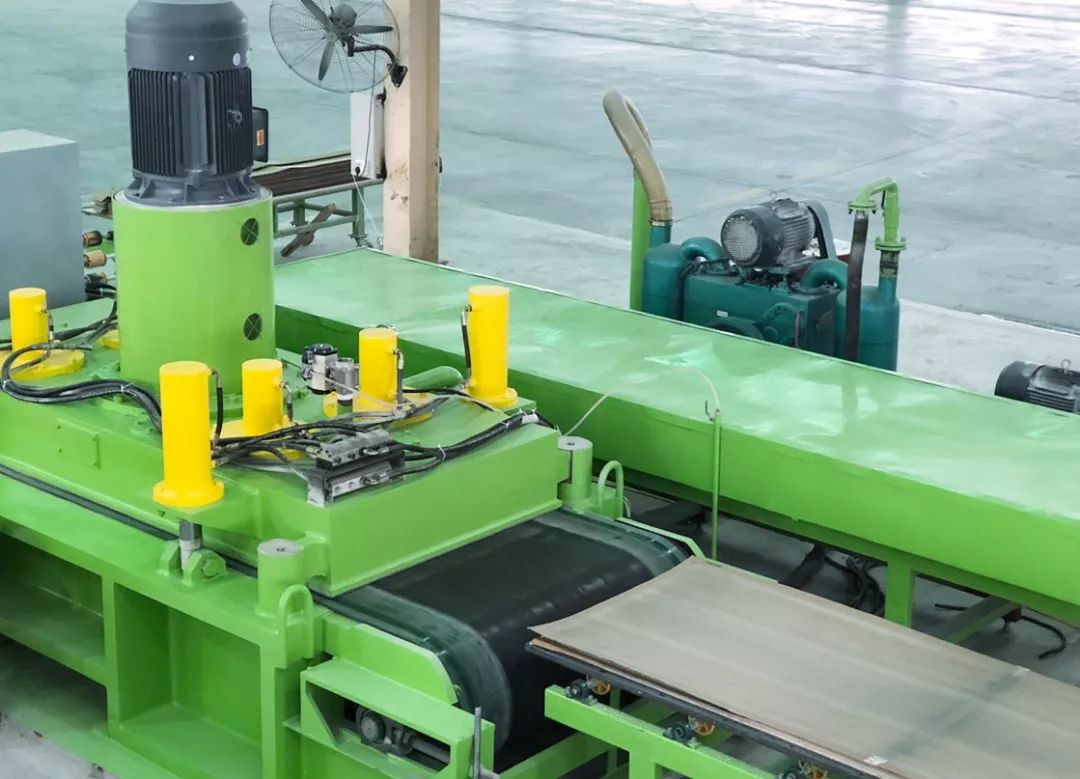

4. Adopt the domestic first-class super-large press, 300 tons of giant working pressure, one-touch start, the whole process of computer control, to ensure the whole pressing and vacuuming process standard as one, to ensure the high density and strong hardness of quartz stone (general small press working pressure 40-50 tons, the finished plate density is low, lightweight).

5. Tunnel curing oven, with curing agent, drying agent, constant temperature 65-70 degrees, after 1 hour and 40 minutes of strict time control drying, to ensure the flexibility of the board while maximizing the hardness and strength of the board.

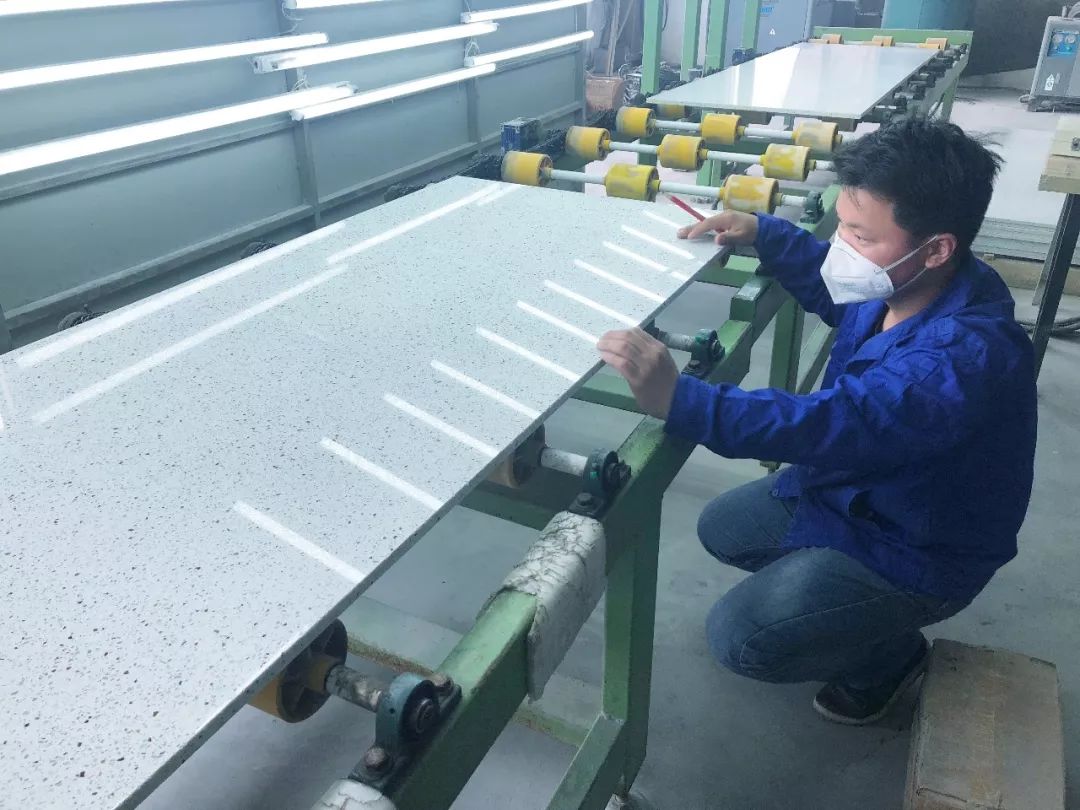

6. Adopt the latest type of polishing equipment, automatic sizing, more accurate and more efficient. Polishing for the first time, so that the surface of quartz stone has glossy and has no scratches. Automatic spray code, each piece of MQ STONE quartz stone has an anti-counterfeit spray code, more guarantee for use! Super Clean & Bright secondary polishing, a single set of polishing equipment equipped with 20 grinding heads and polishing pads from 36 mesh to 3000 mesh continuously, can enhance the efficiency of the polishing process and reduce costs. After the super clean and bright secondary polishing to ensure the MQ STONE quartz stone achieves high gloss, no damage to the surface, no scratches, smooth and stain-resistant excellent quality.

7: Automatic quality inspection to ensure that each quartz stone is scratch-free and uniformly colored. Product quality inspection is equipped with many automatic suction cups and flap equipment, which can not only reduce labor costs and efficiently carry out product quality inspection, but also avoid secondary injuries from manual handling of plates. Daxin's principle: Never leave the factory if the products do not meet the quality standards.

From the above explanation, you should have a deep understanding of the production process of artificial quartz stone, as well as the quality of our company's products. If you have a large residential project in the future and need quartz stone products, please feel free to contact us!