12B/13B, North Building of Pacific Square, No.331, Jiahe Road, Siming District, Xiamen, Fujian, China. 361001

+86-592-5065811

+8615160739809

Natural Stone composite marble tiles are different kinds of natural materials (e.g., ceramic, granite, aluminum, glass, etc.) in combination. The thickness of 3mm polished marble surface bonded to a substrate having a thickness of 9mm on. In applications such as flooring, choosing marble composite tiles for construction projects has many benefits for us. It retains the color and beauty of natural marble. Marble composite tiles are lighter, but very hard, and still very durable. It actually improves the physical properties of natural stone and has a lower risk of breaking during transportation and installation.

Product Details

Chinese Nero Marquina Black Marble Composite Floor Tiles

MQ STONE is one of the earliest founders that invested and researched the new ultrathin natural composited marble panel systems. Our Chinese Black Composite Marble Tile can be composited with different bases. They can be composited with different kinds of marble stone. The base can be porcelain, glass, honeycomb, aluminum honeycomb.

Chinese Black Composite Marble Tile is the combination of natural marble with different kinds of materials such as ceramics, granite, aluminum, glass, and others. A polished marble surface with a thickness of 3mm is bonded to the base material which is 9mm in thickness. There are several advantages for us to choose marble composite tiles for the building projects in the applications such as flooring.

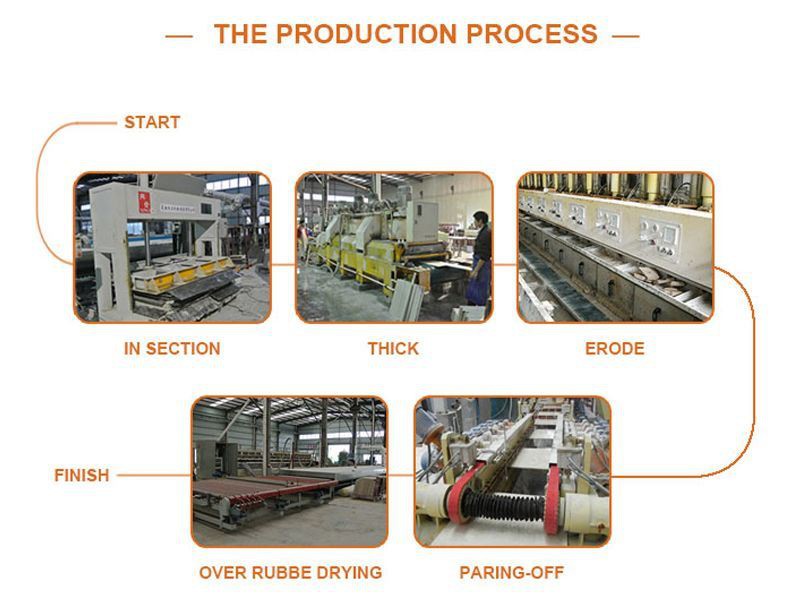

Marble composite board processing procedure:

First, select high-end marble varieties that are marketable and purchase rough tiles with a size of 610*610mm (that is, tiles with no polished upper shaft on the surface).

1. Sawing the rough board: Process the marble blocks on a two-way cutting machine into a rough board with a thickness of 14mm and a specification of 610*610mm, and then dry.

2. Bonding: Lay the rough tiles flat, face-up, and at the same time apply the prepared adhesive on the surface of the rough tiles and one side of the marble slab, and then turn the side with the adhesive slab facing Align the bottom right on the blank tile coated with adhesive; then at the same time apply a thin and even adhesive layer on the top of the marble slab and the front of the other blank tile, and then coat the other piece with adhesive. The rough tiles on the adhesive side are combined with the marble wool board and then pressurized on it, after 24 hours of consolidation.

3. Splitting: Install the composite wool board with the upper and lower rough tiles and the marble in the middle on the horizontal splitting machine, and split into two marble composite wool boards with rough tiles on one side and marble on the other side.

4. Thickness control: Put the marble side of the marble composite wool board up, and control the thickness to the same thickness by the thickness control machine.

5. Grinding and polishing: After controlling the thickness of the marble composite rough board marble and using ten-head continuous grinding and polishing, it becomes a high gloss marble composite rough board.

6. Cutting and chamfering: After grinding and polishing, the marble composite slab is cut into a 600*600mm composite slab by a cutting machine, and then the edges are chamfered to become the finished marble composite slab.

Additional Products

Product Parameters

Product Name | Chinese Black Composite Marble Tile |

Stone Name | Nero Marquina Marble |

Stone Type | Natural Marble+Aluminum honeycomb Base |

Standard Specifications | Panel Width: 1550mm,1650mm,1850mm,etc |

Panel Length:600mm,800mm,1000mm | |

Standard Size: 1250×2450mm,etc | |

Thickness:15-25mm | |

Aluminum Thickness: 0.05mm to 0.50mm | |

Function | Anti-Static |

Surface Treatments | Polished Finish |

Advantages | Lightweight, cheap |

Usage | Indoor, Wall, and floor |

Packing | Seaworthy wooden crate, pallet |

Payment terms | 30% by T/T in advance, balance by T/T before shipment |